JM181 Polypropylene spinning drafting machine is widely used in the industrial fields of Geo-Textile, Failter cloth, Lifting Belts, Cables, FIBC jumbo bags, wig, braiding/knitting products, construction reinforce fiber, sewing thread, rope, fishing net and narrow fabrivc etc.

1. Product Description

for yarn size range: 100D-3600D for yarn tenacity :raw white yarn tenactiy 7.5g/d

1) Pp material get into hopper through automatic loadind units, with pp and auxiliary like color masterbatch and UV etc

2) Extrusion part, pp melt in screw, this part including metering pump etc

3) Melting pp flow into spinning beam, then get into spinneret

4) Yarn will be shaped in spinneret, then air cooling window, two layers to make the wind blow evenly

5) Oil device from two sides to add oil to make yarn smooth and bright

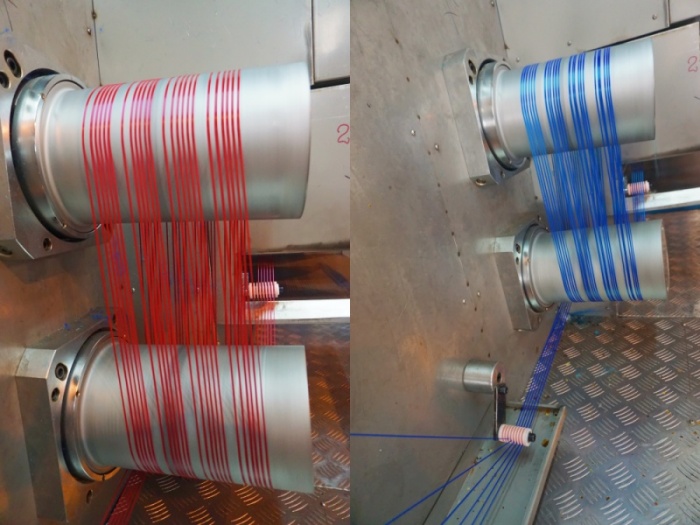

6) 4 groups hot godet +1 heating chamber to make high ratio, tenacity will be 7-7.5g/d

7) Automatic winding system, save labor cost

2. Production Process

Technical process of Polypropylene spinning drafting machine:

Chips→ extruder→ extruding head →melt pipe with static mixer→ spinning beam with oil heating →quenching delay→ quenching chamber → oiling system → feeding roller →migration nozzle→ four pairs of hot godet rollers→ inter lacing jets→ take-up winder →final product

3. Final Products

Our equipment is widely used in the industrial fields of braiding/knitting products , construction reinforce fiber , sewing thread , rope , fishing net and narrow fabrivc etc.

4. Installation & Training

Pre-Sales Service

* Inquiry and consulting support .

* Sample testing support .

* View our Factory .

* With online device , our team is 24hr at your service .

After-Sales Service

* Come engineer help set up machine , take 12-15 days for assemble and trainning . 3-4 days for set up , 5-6 days for training .

* The customer should prepare 3-5 workers for learn and operate the machne .

* With online device , our team is 24hr at your service .

TEL: +86 538 899 6996

E-MAIL: sales@jiameitech.com