1. Product Description

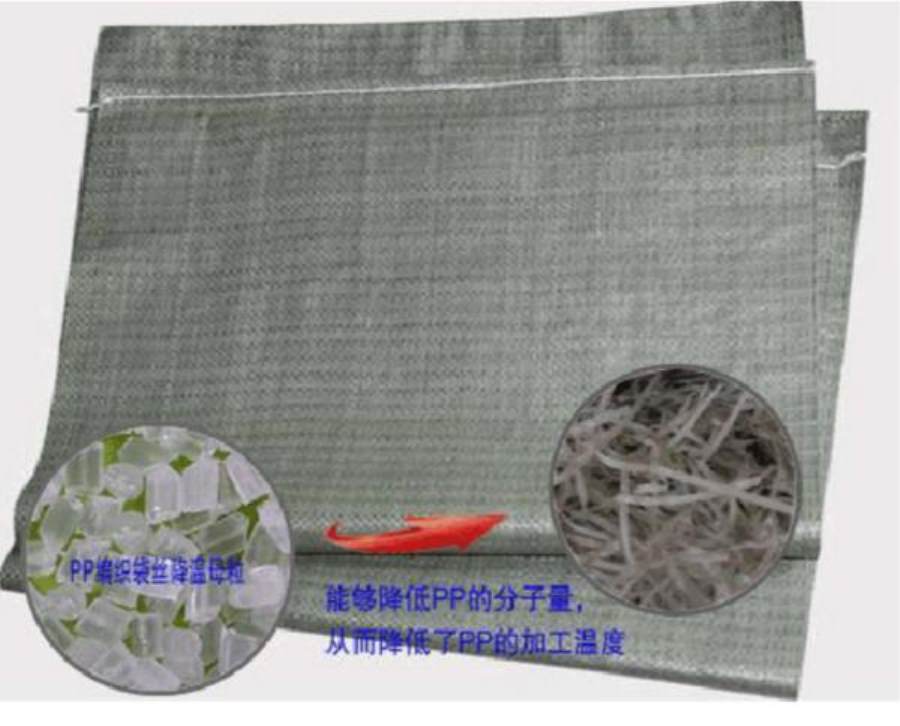

Cooling masterbatch for multifilament yarn spinning machine

Cooling

masterbatch is specially designed to reduce the high viscosity of PP

and prevent the decomposition of other additives such as pigments at

high processing temperature. The cooling masterbatch can reduce the

molecular weight of PP, thus reducing the processing temperature of PP.

Its main ingredient is peroxide. At present, the application scope of

cooling masterbatch has been expanded, and it has become a common

auxiliary in some PP modification enterprises, especially in the

production of high flow PP.

The cooling masterbatch is mainly used

for spinning polypropylene. Because of the high molecular weight of

polypropylene, the spinning temperature is above 300℃. This makes it

easy to decompose auxiliaries and pigments. Cooling masterbatch

generally reduces spinning temperature at 10~50℃ and improves spinning

process. The additives used for cooling masterbatch are actually

peroxides, commonly used as initiator A, di-tert-butyl peroxide (DTBP),

yellowish transparent liquid, boiling point 110℃, ignition point 182℃,

decomposition temperature 193℃ (half-life 1 minute), 126℃ (half-life 10

hours).

2. Physical characteristics

1. Form: particle

2. PP cooling master batch color: white translucent

3. Melt index: <510g/10min

4. Density: 0.93g/cm

5. VEKA softening point: 152℃

3. Function

1.

Adding 0.5-1% PP cooling masterbatch during the processing of PP can

reduce the processing temperature of PP by 20-30 degrees Celsius and

increase the melting index.

2. Plastic grade PP can produce high quality polypropylene, coarse, fine, long and short fiber.

3. The quality of PP blown film, woven bags, injection molding, PP pipes and other products can be greatly improved.

4. PP products can reduce power consumption and improve operation environment during processing.

4. Application

It is mainly used for high filled polypropylene, PP injection products, PP wire drawing, PP woven bag yarn and so on. Increasing the melting index of resin, enlarging the colouring range of resin, reducing shrinkage, strengthening rigidity, reducing extrusion temperature, making the resin stable extrusion and stretching.

TEL: +86 538 899 6996

E-MAIL: sales@jiameitech.com