We are professional manufacturer engaged in multifilament chemical fiber spinning machinery with good experience of 30 years. Our main products include FDY、POY、BCF、ATY multifilament spinning line. BCF melt blown water filter cartridge yarn spinning machine is widely used for melt blown water filter cartridges yarn making.

1. Product Description:

BCF bulk textured yarn spinning engineering --- to PP、PET、PA6 as raw materials, integrated melting extrusion, metered spinning, quenching, drawing, bulking, cooling, mesh, and winding equipment for complete set.

2. Technical data

| Type Specification | Ends/pos. | Pos./line | Spinning speed(M/min) | Max output(T/day) |

| 1600d | 2 | 1 | 1600 | 0.8 |

| 2000d | 2 | 1 | 1600 | 1.0 |

| 2400d | 2 | 1 | 1600 | 1.2 |

| 2600d | 2 | 1 | 1600 | 1.3 |

3. Final Products:

Polypropylene melt blown water filter cartridge yarn spinning machine is widely used for melt blown water filter cartridges yarn making, fluffy and smooth.

3. Machine Parts

Polypropylene melt blown water filter cartridge yarn making machine

1. This machine takes PA/PP as the raw material, and adopts the one-part process of spinning, drafting and deformation to produce BCF yarn;

2. The gravity batching system ensures the accurate proportion of color masterbatch and main raw materials;

3. Special extruder design, suitable for various kinds of polymer production;

4. The solution of the special spinning box is evenly distributed and has no dead Angle,and the circular or rectangular spinning assembly is adopted for convenient replacement and extended cycle;

5. The new type of side-blown air cooling device is adopted, without wind pressure fluctuation, which can adjust the cooling air conditioning to the required temperature, relative humidity, wind speed and air pressure distribution;

6. It is specially designed with a single suction system, which can discharge hypopolymer and lactamide;

7. The cooperation between the new nozzle deforming device and the optimized cooling drum ensures the excellent expansion and crimp setting;

8. The hot roll adopts high frequency heating by reading induction, and the surface temperature of the roll body is even and adjustable;

9. Fully automatic switching winding machine is adopted. The yarn tension is constant, the switching success rate is high and the shape is beautiful.

5. Packing & Delivery

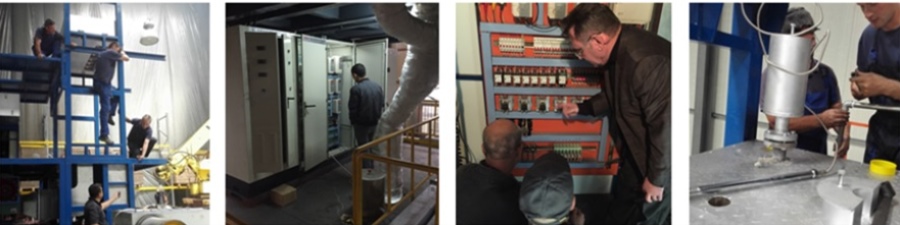

6. Installation & Training

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

* With online device, our team is 24hr at your service.

After-Sales Service

* Come engineer help set up machine, take 12-15 days for assemble and trainning. 3-4 days for set up, 5-6 days for training.

* The customer should prepare 3-5 workers for learn and operate the machne.

* With online device, our team is 24hr at your service.

TEL: +86 538 899 6996

E-MAIL: sales@jiameitech.com